Premium flower is the future of your brand. Control has never been more important...

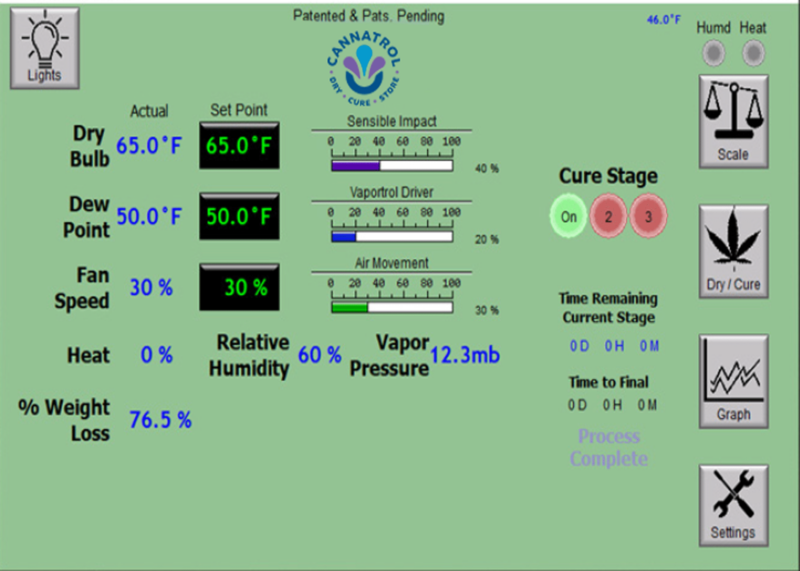

Growing a quality product is a significant financial commitment. Genetics, nutrients, power and labor all get calculated into the cost of the grow cycle. With that much investment in the grow process, it is critical to assure the product is dried and cured in a clean, consistent environment. Anything less can result in a total loss of your harvest.

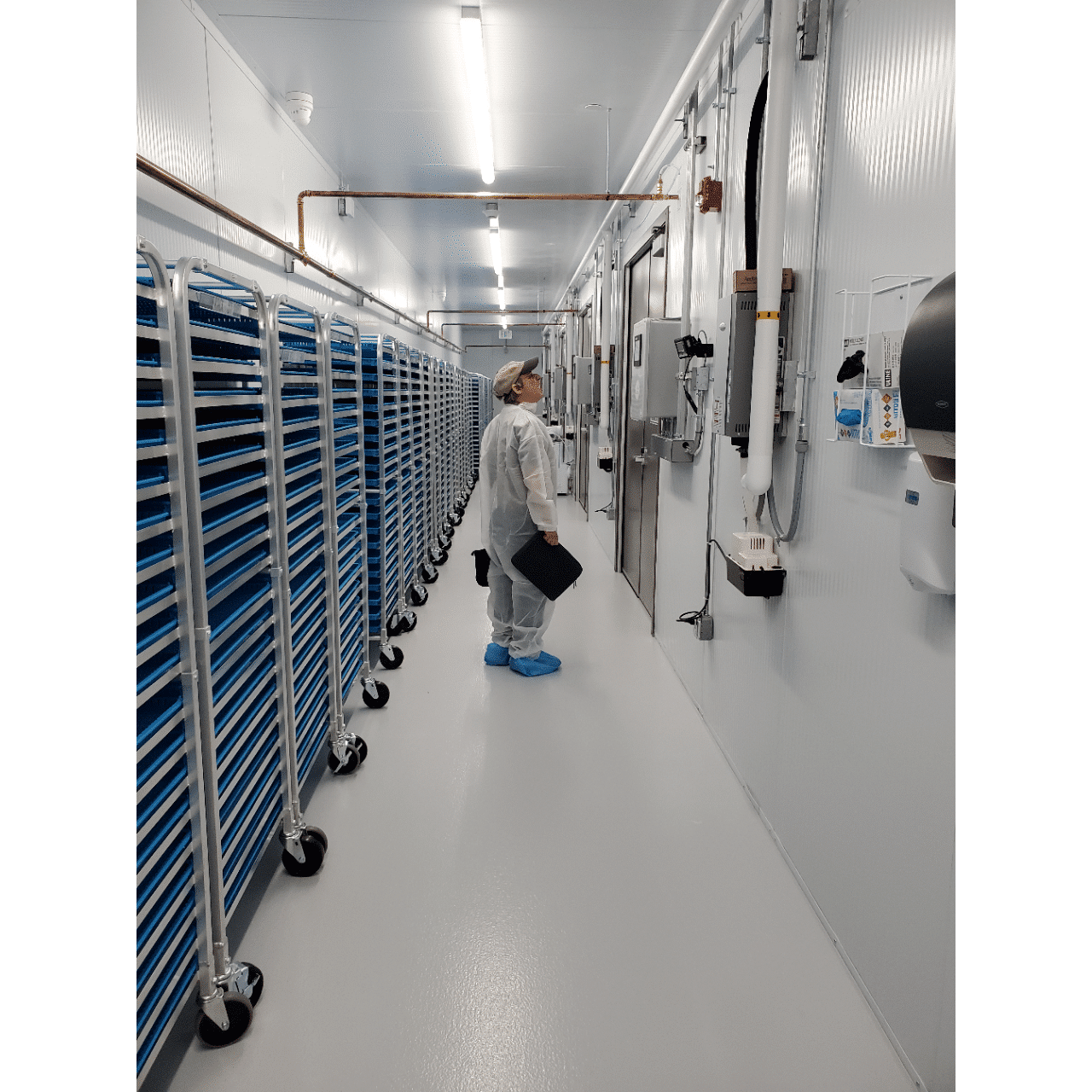

Small batch processing means that you are not loading wet buds in the same room as dry or partially dry buds. This small batch philosophy is what makes our systems unique. With a Cannatrol system you can produce craft quality cannabis on a large scale. The Cannatrol™ System assures not only a terrific aesthetic result with superior organoleptic properties, but can keep your harvest free of pests and mold (both visible and invisible) that can destroy a harvest or worse!